Test the AD6-KanbanEdit software for free:

The Kanban method originated in Japanese industry and means “information label”. It is a visual technique of downstream production and supply management (pull flow). Initially established in the automotive sector, it meets the requirements of all industrial supply chains.

The Kanban method originated in Japanese industry and means “information label”. It is a visual technique of downstream production and supply management (pull flow). Initially established in the automotive sector, it meets the requirements of all industrial supply chains.

Test AD6-KanbanEdit for free and successfully apply the Kanban method

• Quickly implement Kanban in the entire company (production, subcontracting, supplies),

• Establish the Kanban method and adapt it to changes in the company,

• Standardise and automate label printing,

• Measure the impact of different parameters on your stock levels

With AD6-KbE, you can improve your logistics performance using the Kanban method

• Stock reduction between 25% and 50%,

• Internal and external service rate close to 100%,

• Productivity gains between 5% and 10%.

Share real-time quality communication with all players in the industrial flows

• Delegate the daily reality of production to operators,

• Provide time and guidance to the management for forecasting and investing.

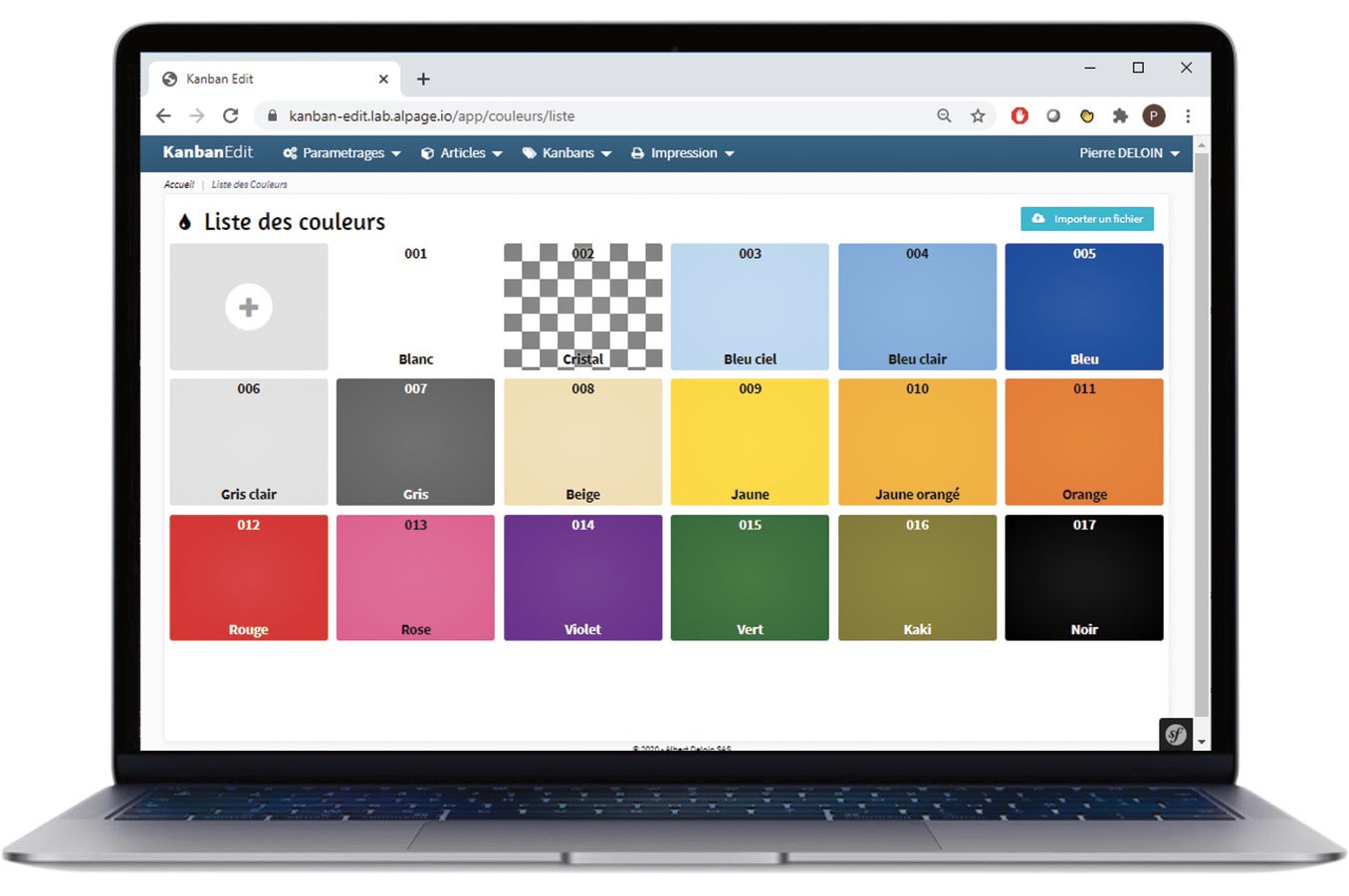

AD6-KbE offers you a user-friendly, powerful and comprehensive tool

• Dashboard customised for each manager,

• Customised lists (filters, sorting, columns),

• ADC import,

• Creating and updating data by importing it,

• Exporting software data,

• Reporting (stocks, management, Kanban fulfilment),

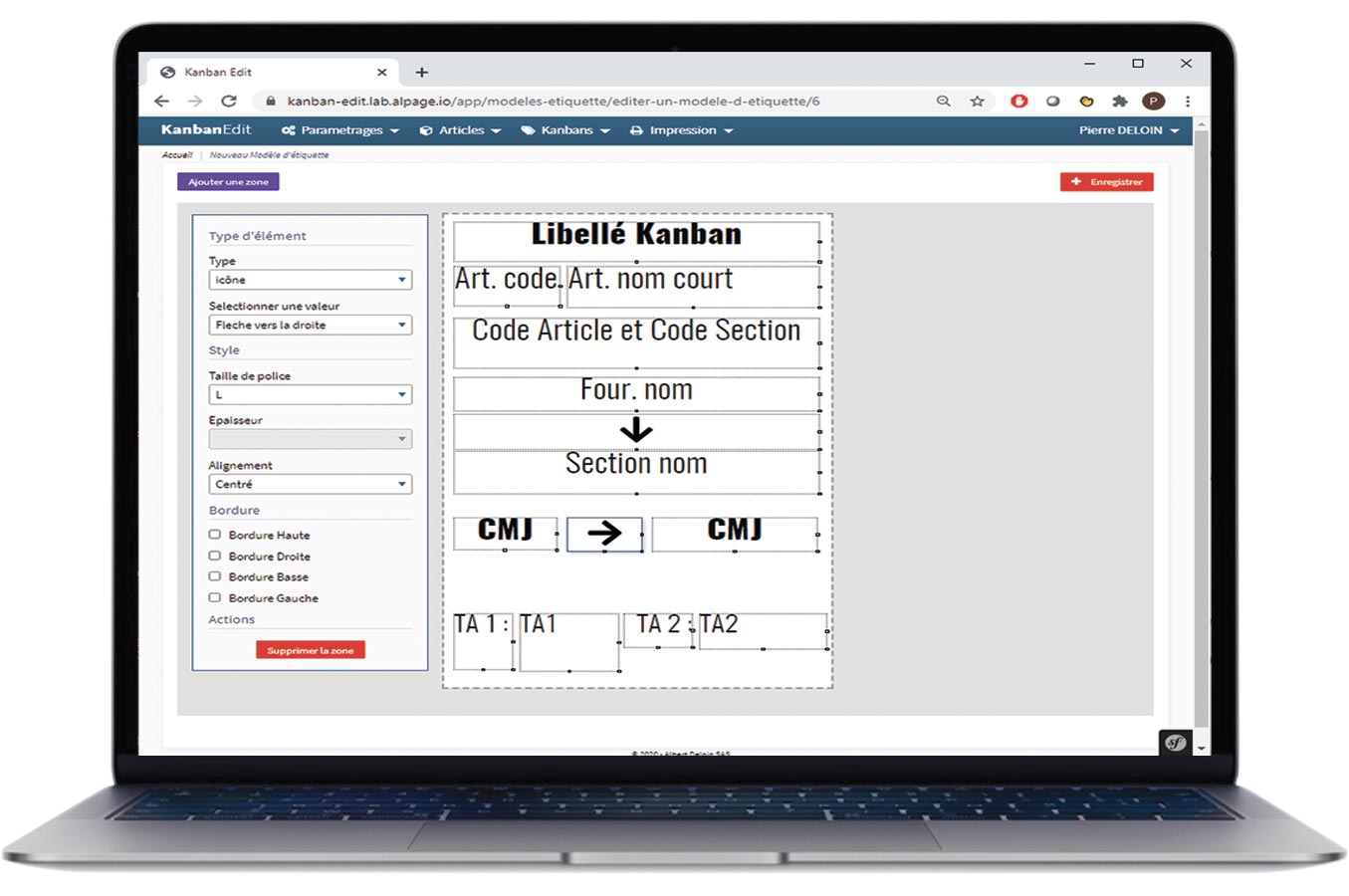

• Creating your own Kanban label templates (font, barcodes, shapes),

• Printing out Kanban labels, etc.

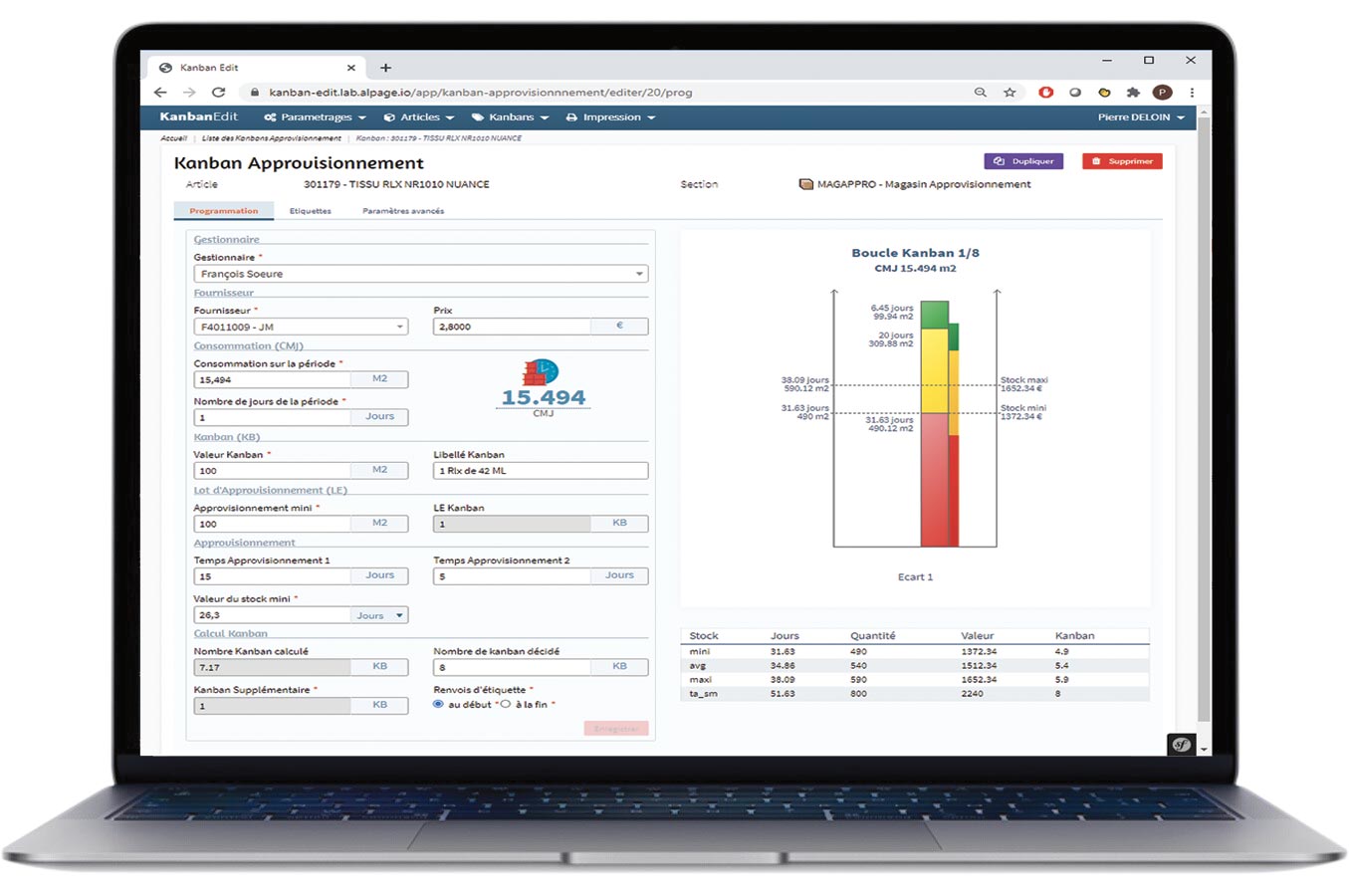

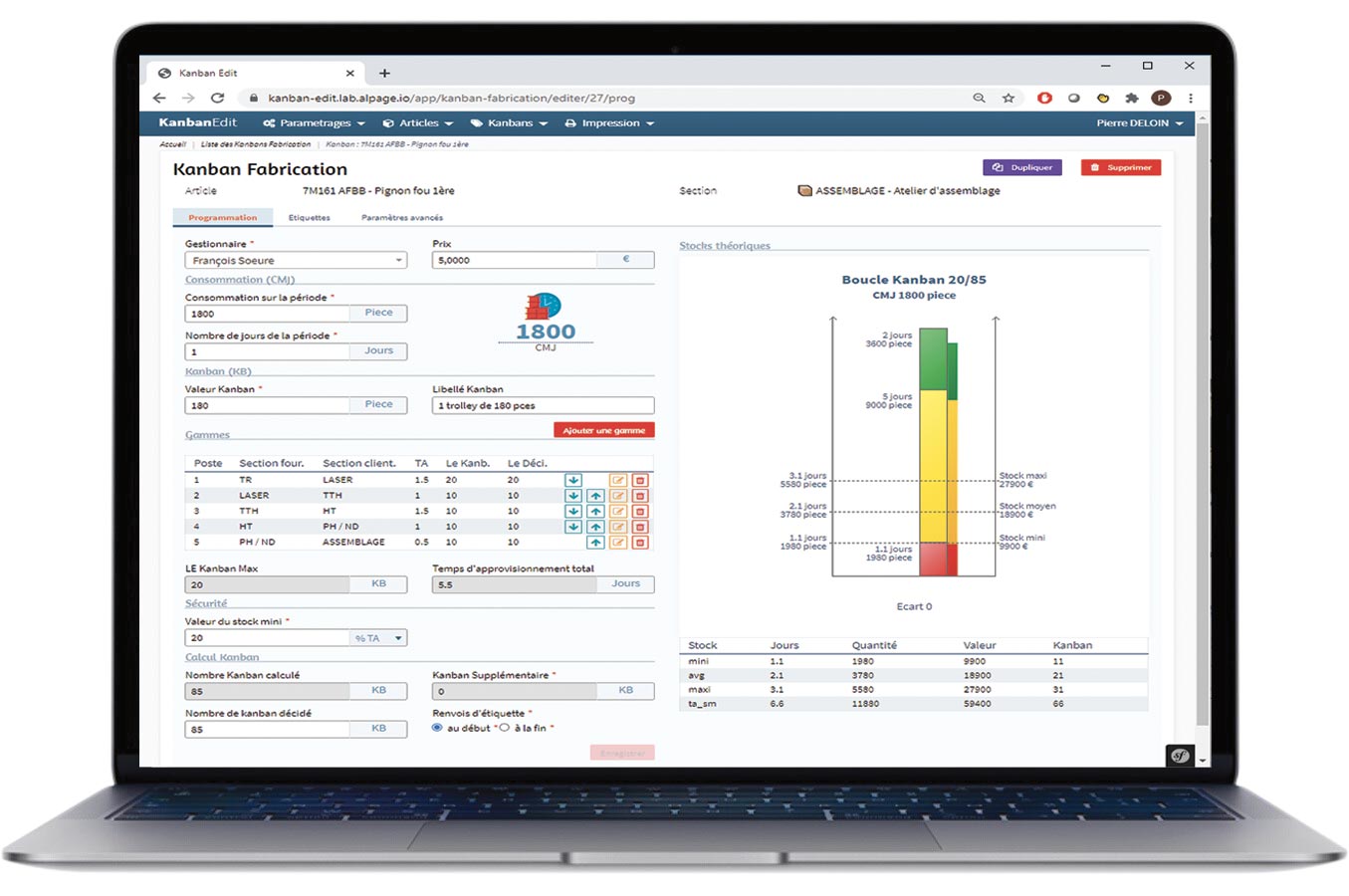

Using AD6-KbE, you can easily manage the Kanban supply, manufacturing and tracking sheet

• ADC (Average Daily Consumption),

• MS (Minimum Stock), EOQ (Economic Order Quantity),

• EOQ calculated according to the Kanban value,

• Total number of Kanban labels needed,

• Minimum, maximum and average stock expressed in quantity, days and value, trigger thresholds, etc.