Define the pull flow rules adapted to your company, choose the tools to use (Kanban, pulled flow AD6, DDMRP) and take advantage of the AD6 software range.

How to plan and manage your supply chain in 5 points:

- Define the pull flow rules to fit the company’s objectives (commercial policy, inventory value, etc.) as well as the industrial constraints.

- Decline the pull flow rules for each item (products, components, materials, etc.) and determine the configuration: management based on stock or on demand, lead time, security, etc.

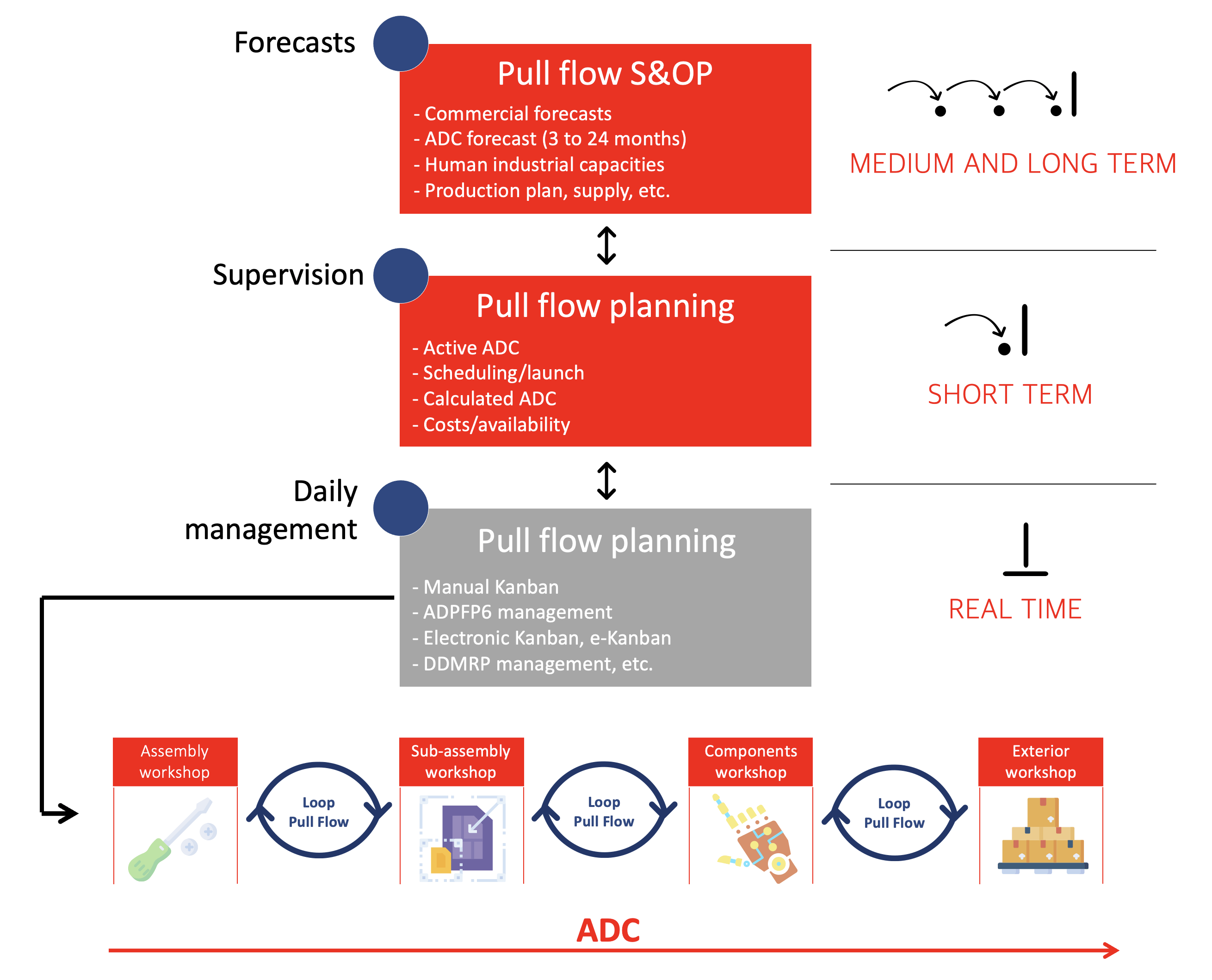

- Choose the daily pull execution tools (manual Kanban, electronic Kanban, PFP6, DDMRP) and software (AD6 range).

- Set up short-term tools for controlling and monitoring the settings:

– Monitoring consumption (ADC), security, etc.

– Costs/capacities, etc. - And medium/long-term analysis tools that use forecasts.

MRP / pull flow – what is the main difference?

Pull flow supply chain planning and management use the same input data as MRP (push flow). So what is the difference? For MRP, forecasts trigger needs (OF, purchase orders), while in pull flow they are used to size the level of activity (configuration), and the needs are triggered by real consumption.

Take a look at our software for monitoring and planning in pull flow systems.