AD6-Pln software

AD6-Pln includes all the functionalities of AD6-FxT supplemented by the following elements: managing human and industrial capacities, decision-making tools and load and capacity control, queue management (GANTT), load plans across time.

AD6-Pln meets the objectives of pull flow systems: Just-in-time (JIT), real time and responsiveness at all levels of your supply chain

• No need for a net calculation of needs,

• Regardless of the volume, seasonality and diversity of commercial needs,

• Products managed from stock, to order, seasonal products, etc.

• Using a single parameter: Average Daily Consumption, your supply chain can resize all flows in real time.

With AD6-Pln, you can plan, manage and optimise your pull flow supply chain

• Short, medium and long term view,

• Products are delivered from stock or on demand,

• Small, medium and large series,

• Customer-Supplier relations analysis,

• Organisation supervision,

• Controlling and updating the ADC and pull parameters,

• Automatic resizing of pull flow loops,

• Managing human and industrial capacities,

• Managing exceptional needs, seasonality, facility and supplier closures,

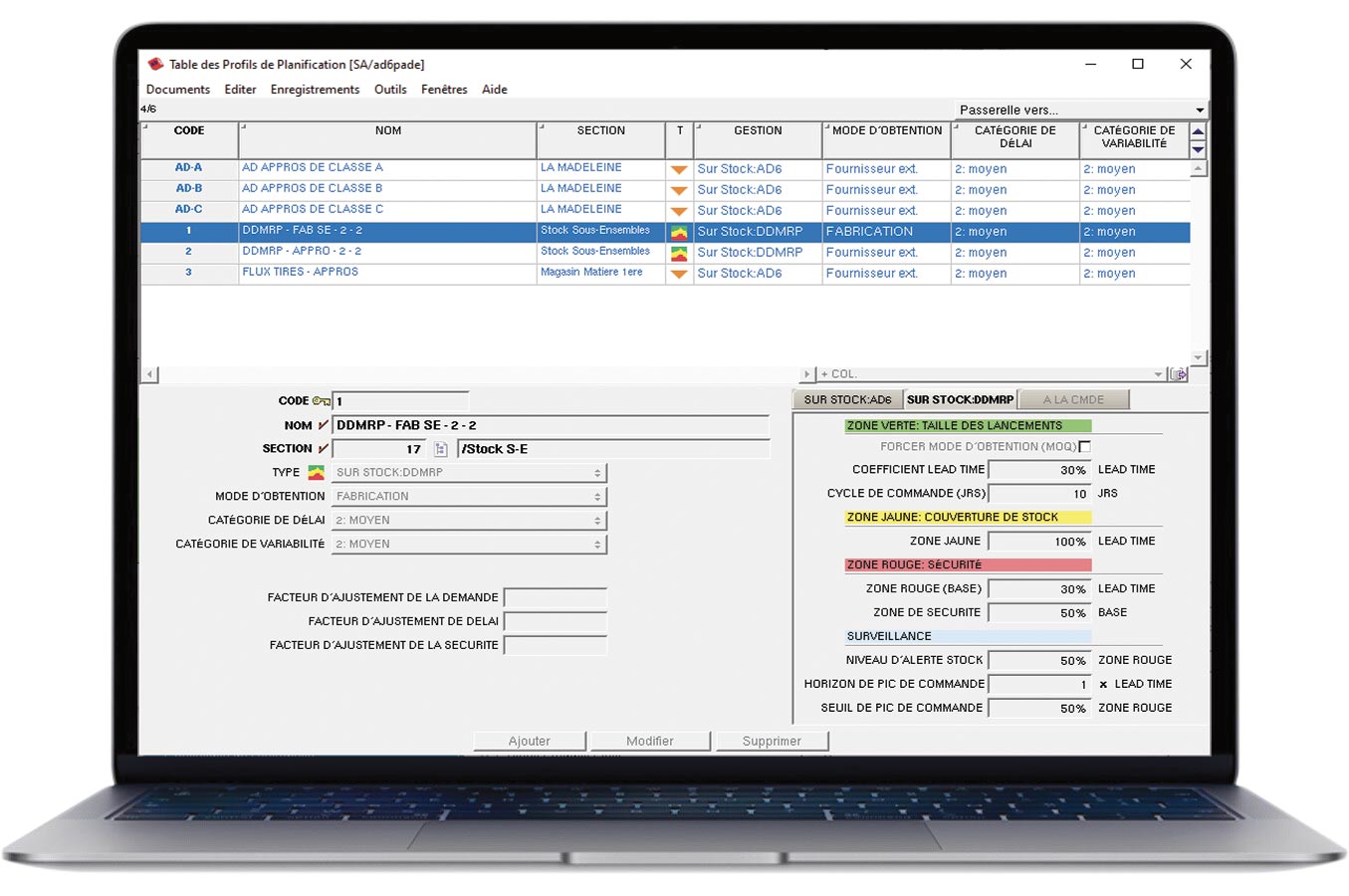

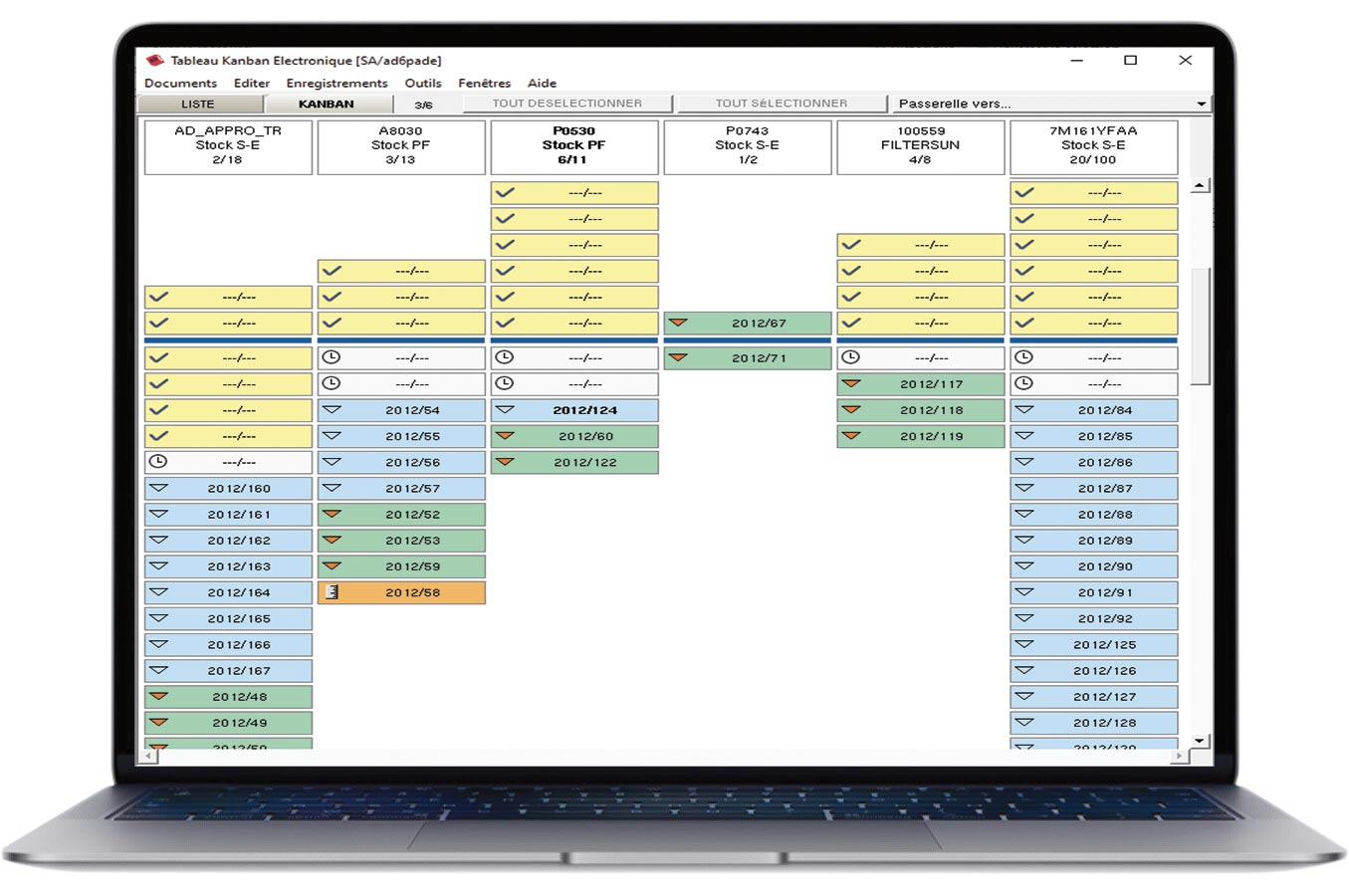

• Universal use: Manual Kanban, e-Kanban, PFP6 and DDMRP.

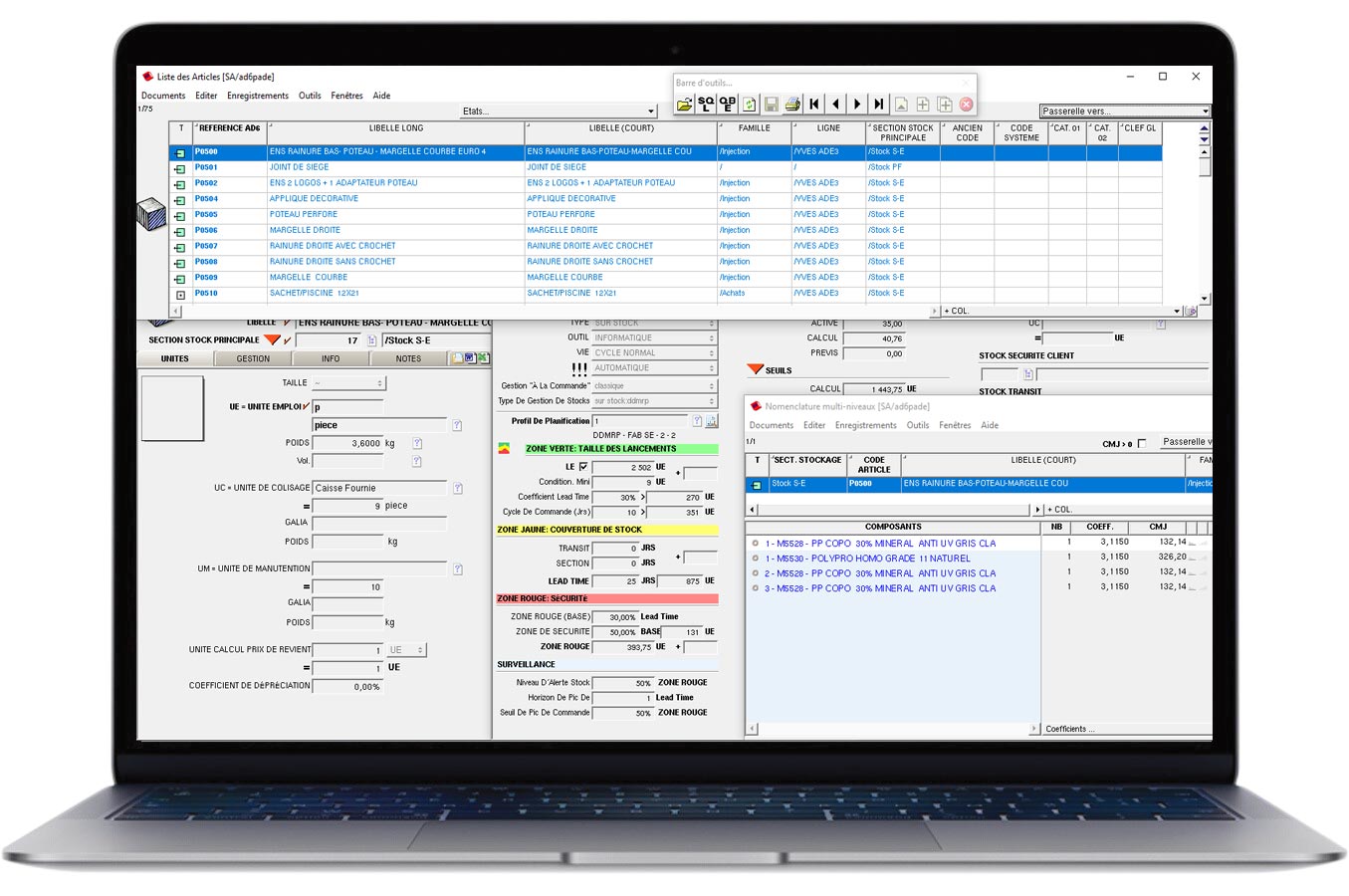

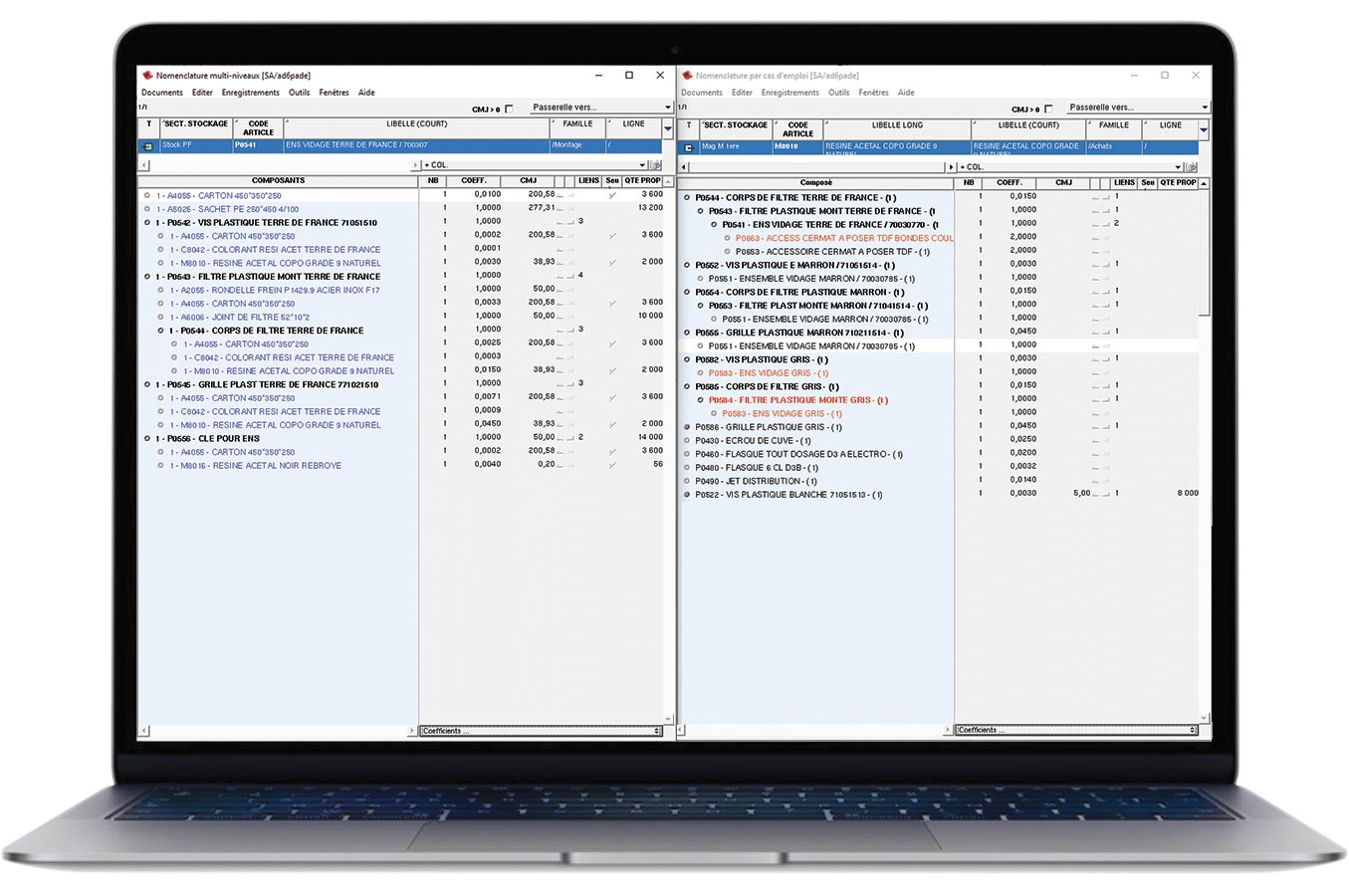

AD6-Pln allows complete management of the company’s technical data

• Dividing the company into sections,

• Table of types of packaging: boxes, pallets, etc.

• Weight and volume management,

• The same item can have different scheduling parameters depending on where it is stored and who manufactures it,

• Types of scheduling: stock, on order, seasonal, etc.

• Methods of obtaining: Manufacturing, supplier orders, subcontracting, etc.

• Range, nomenclature, waste management and recovery,

• Cycle time, operator time, adjuster time, machine time, assembly time.

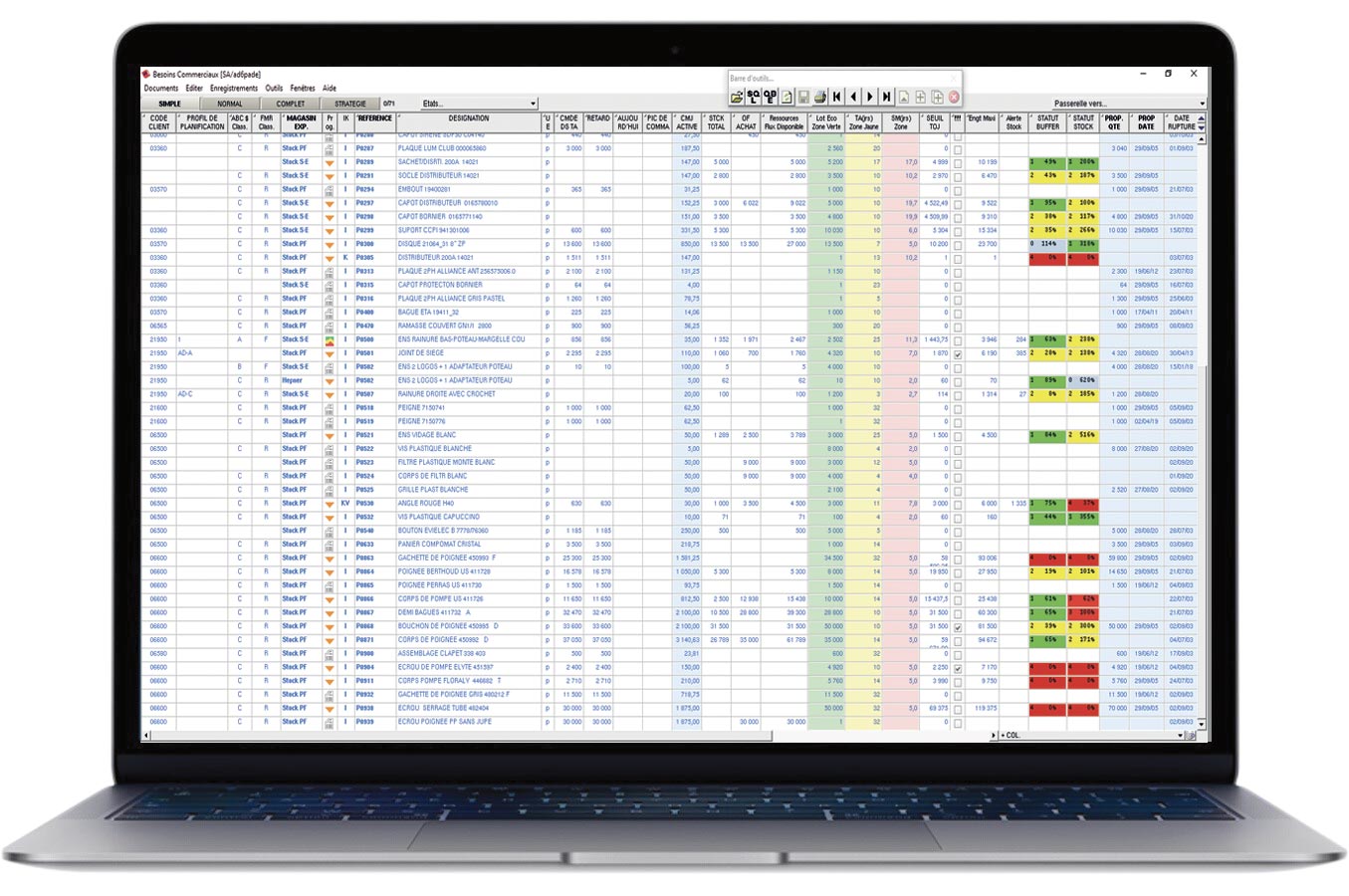

AD6-Pln provides dashboards adapted to each sector of the company: Dashboard of needs

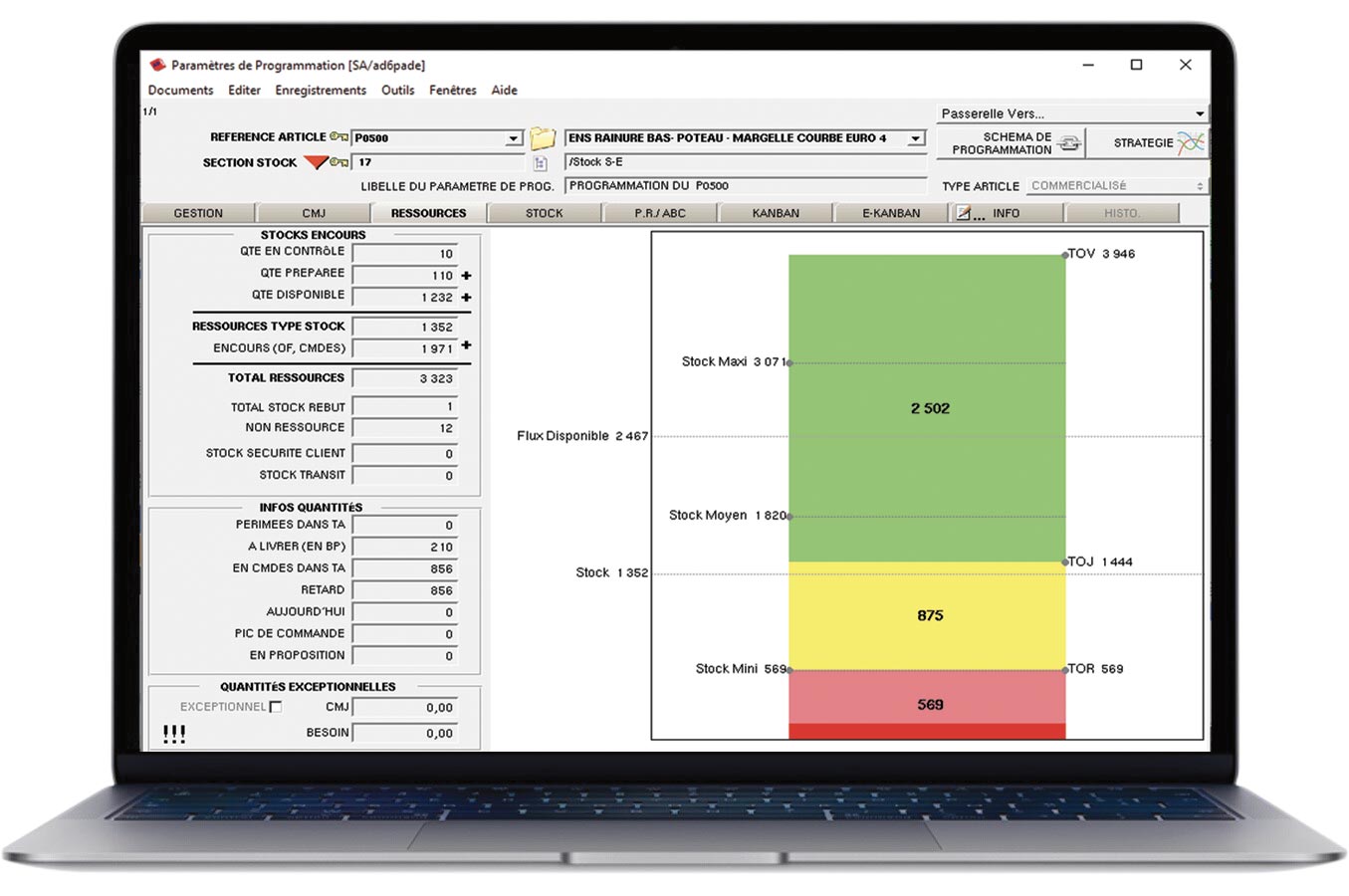

A valuable decision-making tool for all parts of the supply chain: production, manufacturing, supply, etc. AD6-Pln is updated in real time and proposes the quantities to be manufactured/ordered using the calculated pull flow need. This calculation takes into account the following:

• Type of item: stock or on demand management,

• Management mode: Kanban, e-Kanban, PFP6, DDMRP,

• Pull flow parameters: ADC, TA, EOQ, MS,

• Customer and supplier order book,

• Stocks and work in progress.

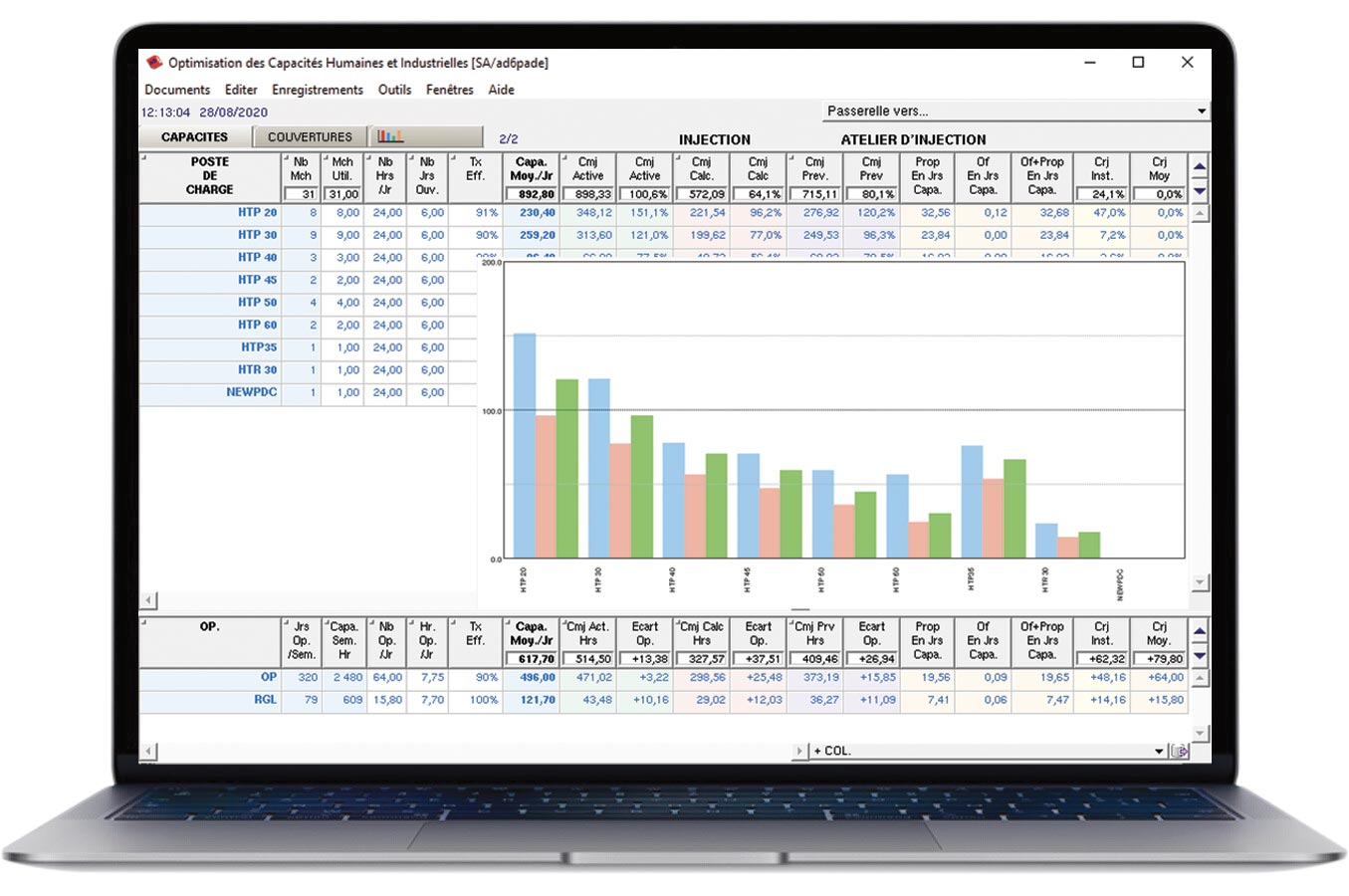

Dashboard “Optimisation of human and industrial capacities”

This decision-making tool allows you to compare load and capacity and anticipate needs by simulating activity forecasts (month, quarter, semester, etc.)

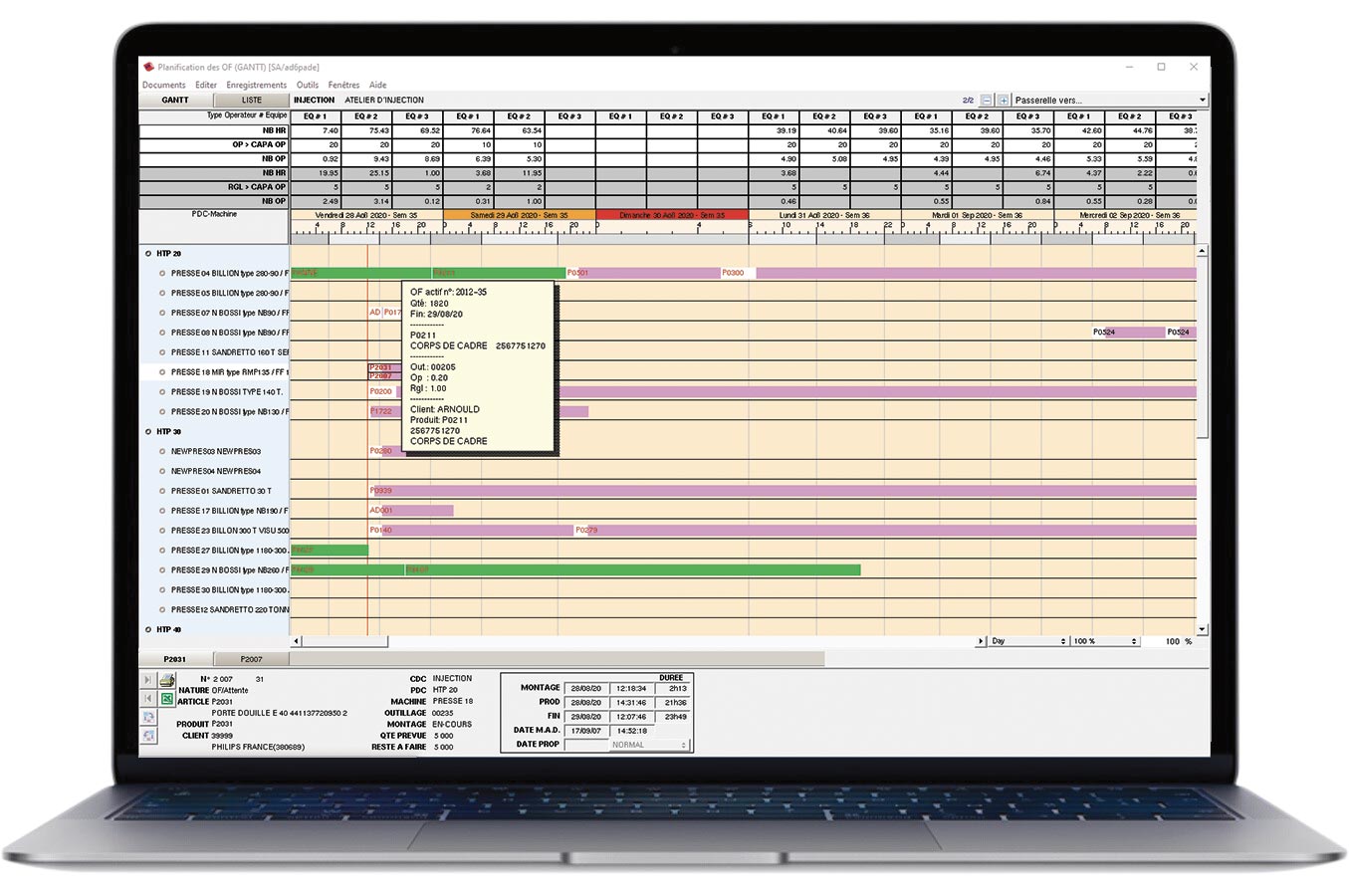

GANTT diagram

It offers a clear view of queues: decision elements for moving fabrication from one machine to another or for arbitrating the fabrication order.

Synchronization between AD6-Pln and your ERP is done in real time

The interfaces between AD6-Pln and your ERP are grouped together in a single piece of software: AD6-Exchange. It automatically manages all the information flows between AD6-Pln and the ERP in real time. All the events entered daily into the information system are synchronized in real time using AD6-Exchange and automatically transferred to AD6-Pln.

AD6-Pln helps improve your industrial performance

• Stock reduction between 25% and 50%,

• Internal and external service rate close to 100%,

• Productivity gains between 5% and 10%.